Neoprene FKM/Nitrile/Edpm/Silicone Inflatable Expansion Joint Dust Boots Rubber Bellows

Xiamen Better Silicone Rubber Co., Ltd.- Material:EPDM

- Capability:Acid Alkali Resistant Rubber Hose

- Color:Black

- Materials:Rubber, Silicone, EPDM, Nitrile, FKM, Neoprene

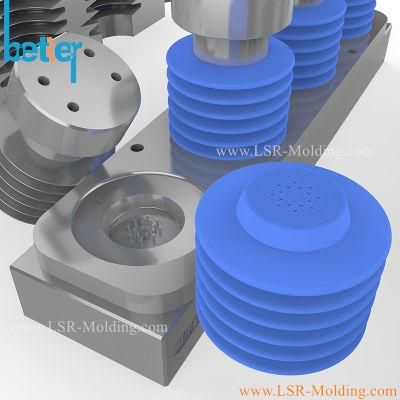

- Forming:Rubber Compression&Injection Molded

- Hardness:30-90 Shore a

Base Info

- Model NO.:RB-01

- Function:Anti-Dust & Water & Oil & Grease & Acids etc

- Applications:Machinery, Automobile, Medical Device etc.

- Working Temperature:-40c~230c

- Design Type:Tapered, Straight, Metal Rubber Overmolding etc.

- Surface Finish Process:EDM, Matt Smooth

- OEM&ODM:Yes

- Typical Applications:Expansion Joint, Covers, Sealing etc.

- Transport Package:PP Bags, Carton Boxes

- Specification:SGS, ROHS, FDA etc.

- Trademark:Better

- Origin:Xiamen, China

- HS Code:39241000

- Production Capacity:100, 0000,Month

Description

(dry heat)

Ozone

Resistance

Material

(Neoprene)

can be compounded for FDA applications

Good Oil Proof

Good Weather Proof

Widely Applications

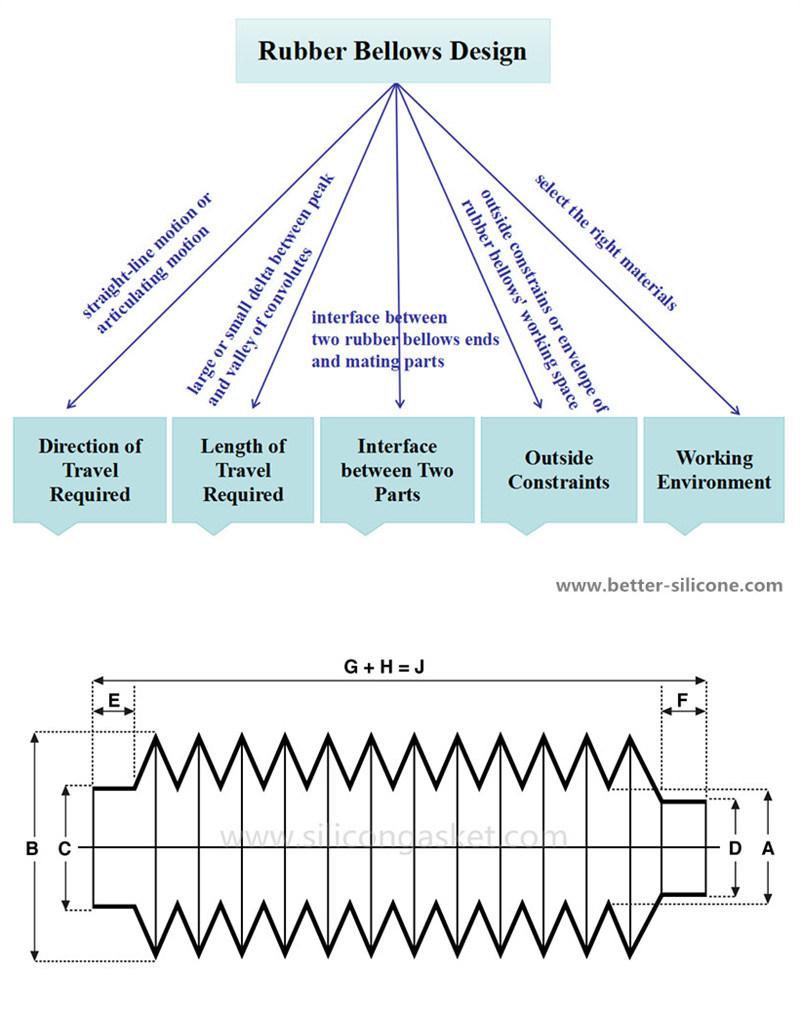

Rubber Bellows Design Guide

Rubber Bellows Some Typical Applications

Expansion joints

Rod & Ball screw covers

Piping penetration seals

Fan duct connections

Compressor and engine intake and exhaust manifold connections

Different Silicone Rubber Bellows durometer demands, surface demands, parting lines demands or rubber flashing demands have different production difficulty and production cost. Epecially for mold-making technology demands, compression mold steel choice, mold maintain when mass production etc.

Custom Rubber Expansion Bellows Requirements:

1. Offer 2D, 3D design drawings or samples, and also tell us your sizes telorance demands.

2. Bellows Materials Demands: Rubber, Silicone, EPDM, Nitrile, etc, or tell us operating environments, functions etc.

3. Durometer Demands (Hardness Shore A):

4.. Silicone Bellows Surface Demand

5. Working Environmment Demands

6.Silicon Bellows Flashing Demands etc.