Rubber Liquid Silicone Product Injection Mold/Overmolding

Zhongshan Melon Rubber & Plastic Products Co., Ltd.- Material:NBR,Nr,EPDM, Fvmq,HNBR,LSR,Cr,Silicon,PU

- Application:Machinery, Industrial Component, Electronic Product, Vehicle, Household Appliance, Customized

- Effect:Rotary Seal

- Cross-Section Shape:O-Ring,Rectangle Ring,D Ring,Customzied

- Hardness:20-90 Shore a

- Temperature:-30ºC-120ºC

Base Info

- Model NO.:ML18206

- Detection:RoHS,Reach,SGS,FDA Conform

- Lip:Flat, Lips,Customzied

- Tolerance:DIN ISO3301,N FT47-001,Rma,DIN7715

- Processing Way:Compression,Injection,Injection Transfer,Extrus

- Transport Package:Bulk Packing

- Specification:Customized

- Trademark:OEM

- Origin:Made in China

- HS Code:4016101000

- Production Capacity:1000

Description

Basic Info.

Model NO. ML18206 Detection RoHS/Reach/SGS/FDA Conform Lip Flat/ Lips/Customzied Tolerance DIN ISO3301/N FT47-001/Rma/DIN7715 Processing Way Compression/Injection/Injection Transfer/Extrus Transport Package Bulk Packing Specification Customized Trademark OEM Origin Made in China HS Code 4016101000 Production Capacity 1000Product Description

Custom Silicone Rubber Compression Mould for Rubber Product, including injection mould/ Liquid silicone injection mould and so onOne- Stop service (mold drawing design mold processing, free sample reference from new mold)

of course, if you do not have an idea about the material

our team could give your professional advice, no matte mold material or parts material ( such as NBR, NR, EPDM, or silicone or liquid silicone)

Rubber Compression Mold , rubber mold, mold, injection mold, transfer mold

1.

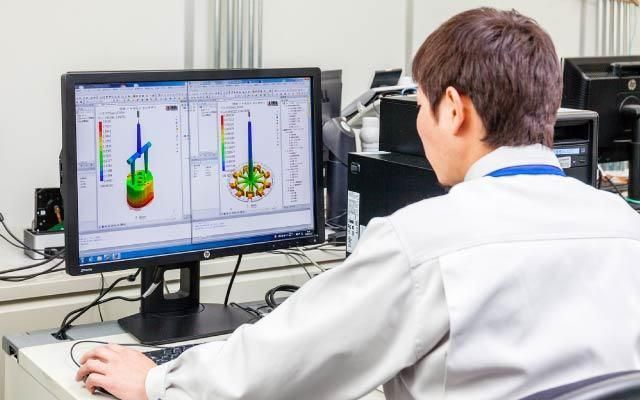

Mold Flow Analysis In Melon before mold processing, to ensure parting line, injection gate, trimming and so on

2. 3-D drawing design and then to make mold processing in Mold Processing Center

3. Rubber&LSR Mold

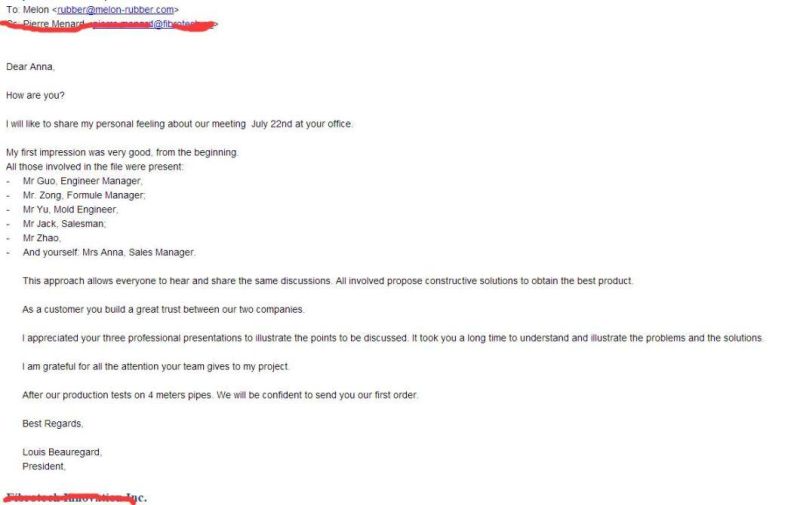

Canada Client Visiting Melon Feedback Why choose Melon for Their Pipe Project

Melon Rubber&Plastic is specializing in the manufacturing of precision rubber molding services including: rubber compression molding, rubber transfer molding, and rubber injection molding enabling us to meet all of your product specifications depending upon our customer's requirement. we own internal tool making facility to minimize production costs and control extremely tight tolerances. We provide molded rubber product fabrication quantities from prototypes and short runs to large production runs.

Even If you do not have a technical drawing, Melon Rubber&Plastic has the ability to reverse engineer your product for you directly from a sample. From simple to highly complex rubber shapes, we takes pride in our ability to consistently produce accurate molded rubber products guaranteed to meet your exact specifications and function perfectly within your application.