Multi-Ply Heat Resistant Textile Rubber Conveyor Belt

Shandong Longli Belts Co., Ltd.- Type:Conveyor Belt

- Feature:Wear-resistant, Heat-resistant, Tear-resistant, Flame-resistant, Cold-resistant

- Performance:Automotive Sealing Strip

- Material:Strong Rubber Conveyor Belt

- Application:Cement, Coal Mine, Quarry, Steel, Iron etc

- Supply Ability:10000 Meter Per Month

Base Info

- Model NO.:EP Series

- Transport Package:International Packing

- Specification:ISO, CE OR OEM

- Trademark:SHUOLONG

- Origin:Shandong, China

- HS Code:40101200

- Production Capacity:20000meter,Month

Description

Project

The minimum value Mpa

after wearing out

type interlayer of clothtype I type II type III variable range Hardness Difference before and after ageing (IRHD) ±20 Max. Value after ageing (IRHD) 85 Tensile strength variable rate in performance <= 25 30 40 Min. value after ageing Mpa 12 10 5 Rate of elongation at break variable rate in performance% <= 50 55 Min. value after ageing 200 180 type I type II type III First quality 0.8 1 1 accepts 1 1.2 1.2

Thickness of the cover layer

≤1.5mm

Thickness of the cover layer

>1.5mm

The average value

of the longitudinal specimen shall be

no less than

The peak value

of the longitudinal specimen

AdhesionTensile Strength Elongation at break Abrasion Cover to Ply Cover to Ply DIN 22102 Mpa % mm3 N/mm N/mm (<=1.5mm) (>1.5mm) DIN 22102-Z 15 350 250 3.5 4.5 DIN 22102-W 18 400 90 3.5 4.5 DIN 22102-Y 20 400 150 3.5 4.5 DIN 22102-X 25 450 120 3.5 4.5 Standards Cover Rubber Adhesion Tensile StrengTD Elongation at break Abrasion Cover to Ply Cover to Ply Ply to Ply AS 1332 Mpa % mm3 N/mm N/mm N/mm (<=1.9mm) (>1.9mm) AS 1332-N17 17 400 200 4 4.8 6 AS 1332-M24 24 450 125 4 4.8 6 Standards Cover Rubber Adhesion Tensile StrengTD Elongation at break Abrasion Cover to Ply Cover to Ply Ply to Ply RMA Mpa % mm3 N/mm N/mm N/mm (<=1.6mm) (>1.6mm) RMA-I 17 400 3 4.4 4 RMA-II 14 400 3 4.4 4 Standards Cover Rubber Adhesion Tensile StrengTD Elongation at break Abrasion Cover to Ply Cover to Ply Ply to Ply SANS 1173 Mpa % mm3 N/mm N/mm A 18 400 70 5 7 C 20 400 150 5 7 M 25 450 120 5 7 N 17 400 150 5 7

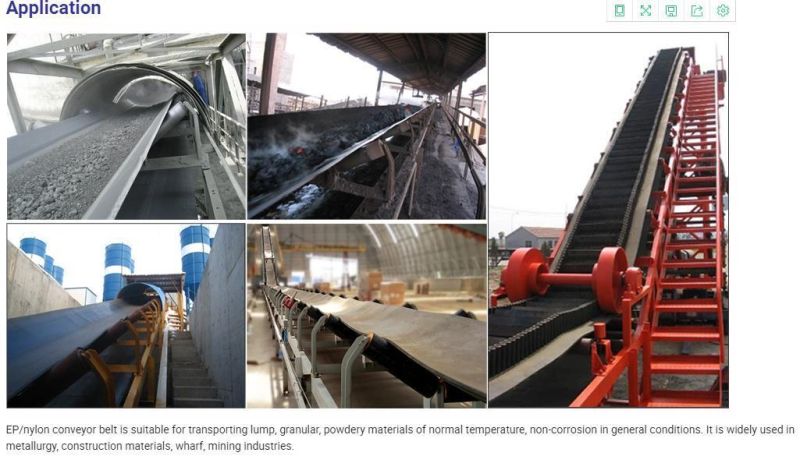

Application

Specification:

Specification:

1) Fabric code: EP100~EP400, NN100~NN400, TN/C & CC2) No.s of ply: 1~10

3) Width: 300~2000mm

4) Thickness: 6~30mm

5) Delivery time: 20~30 day for general orders Classify by structure:Type 1: Same as general use conveyor belt, composed of carcass and cover rubber on top and bottom sides.

Type 2: With an additional insulation layer between crubber cover and carcass.

Classify by varying heat resistant degree:

Type T1: To stand a testing temperature≤100°C;

Type T2: To stand a testing temperature≤125°C;

Type T3: To stand a testing temperature≤150°C;

Type T4: To stand a testing temperature≤175°C.

Characteristics:1. Belt body light and thin,

2. High tensile strength,

3. Moisture resistant,

4. Fatigue resistant,

5. Impact resistant,

6. Excellent trough ability,

7. Good thermal stability etc.

Advantage:

1. Thin belt body with high strength, light weight.

2. Anti-abrasive, impact resistant, corrosion resistant

3. Softy belt body, good flexibility, excellent trough.

4. Vulcanization molding

5. Long service life

Application:Widely used in metallurgy, building material and foundry industries, to convey sintered-ores.

Standards offered

GB/T9784, DIN22102, BS490, AS1332, RMA, JISK6322, SABS1173 etc.

Why choose us?

1. High level of choosing upstream supplier: like carcass, Wuxi Taiji being our strategic partner supplying qualified fabric.

All raw materials purchase is accompanied with quality test certificate.

2. Strict QC system over the whole process of production: raw materials - semi-finished product - finished product

Every one step of semi-finished product shall be tested before next step of processing. Unqualified pieces are now allowed for next step of processing.

3. All finished products shall get tested, and onlt qualified products can leave factory.