Liquid Silicone Rubber for Gypsum Board

Shenzhen Hong Ye Jie Technology Co., Ltd.- Raw Material:Natural Rubber

- Material:Silicone Rubber

- Appearance:Liquid

- Form:Liquid Rubber

- Color:White

- Purity:100%

Base Info

- Model NO.:HY625

- Application:Silicone Rubber for Resin Craft

- Sample:Free

- Technical Support:Free

- Certifications:SGS, MSDS, RoHS, FDA

- Transportation:by Sea or by Air

- Brand:Hongye

- Transport Package:20kg,Drum 200kg,Drum

- Specification:RoHS, ISO-2001, SGS

- Trademark:Hong Ye Silicone Rubber

- Origin:Shenzhen

- HS Code:39100000

- Production Capacity:8tons Per Day

Description

Basic Info.

Model NO. HY625 Application Silicone Rubber for Resin Craft Sample Free Technical Support Free Certifications SGS, MSDS, RoHS, FDA Transportation by Sea or by Air Brand Hongye Transport Package 20kg/Drum 200kg/Drum Specification RoHS, ISO-2001, SGS Trademark Hong Ye Silicone Rubber Origin Shenzhen HS Code 39100000 Production Capacity 8tons Per DayProduct Description

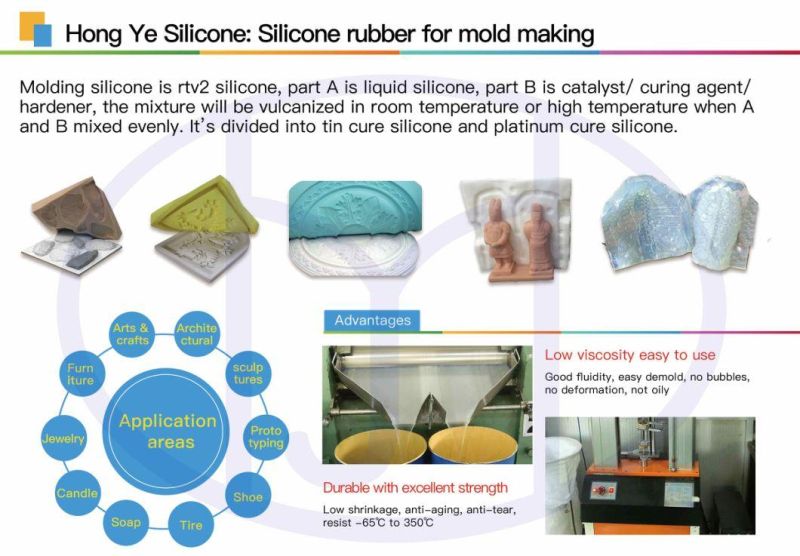

liquid silicone rubber for gypsum boardApplication of liquid silicone rubber for gypsum board

1. RTV liquid silicone rubber is suitatble for toys, gifts,human replica mold making

2. RTV liquid silicone rubber is used for decoration, plate engrave,art crafts mold making

3. RTV liquid silicone rubber is maily applied for resin crafts, unsaturated resin crafts mold making

4. RTV liquid silicone rubber can be used for poly resin crafts, candle crafts, plastic crafts mold making

5. RTV liquid silicone rubber is good for stationeries, plaster crafts, Bunddhist statue crafts, etc mold making

Description of liquid silicone rubber for gypsum board

Itis white or red flowing liquid with general hardness of 22-50 shore A after curing. Molding silicon rubber is a kind elastic silicon rubber mold which features with resistance to deformation, high-temperature, acid-alkali and expansion as well as high reproduction times, good tensile strength, tear strength and elongation.

FAQ. Why the liquid silicone rubber for gypsum board just can be reproduced for a few times?

It can be due to the following reasons:

a. Adding too much silicone oil in to silicon rubber. Silicon oil is an additive which destroies the molecular weight of silicone rubber and reduce the tension and tear strength.

b. Using the silicon rubber with a high hardness to make molds for small sized products with delicate and intricate designs and the silicon rubber with a low hardness to makes molds for large sized products with simple designs.

(Notes: we should choose the silicon rubber specifically according to the requirements of our products to avoid this problem.)

Datesheet of liquid silicone rubber for gypsum board

| Property | 625# | 630# |

| Hardness (Shore A) | 25 | 30 |

| Tensile strength, MPa | 3.1 | 3.6 |

| Elongation @ break, % | 580 | 550 |

| Tear Strength (N/mm) | 25 | 32.6 |

| Linear shrinkage (%) | 0.3 | 0.3 |

| Viscosity | 19000-22000 | 23000-25000 |

| Color | Off White | Off White |

| Mixing ration | 100:5 | 100:5 |

| Pot life | 40 minutes | 30 minutes |

| Cure time | 4-5 hours | 4-5 hours |

Advantage of liquid silicone rubber for gypsum board

Low visocisty ---Easy for pouring operation

High tensile strength --high copy times

Low shrinkage

mixing ratio 1:1 , easy for operation

SHELF LIFE of liquid mouldable silicone

Twelve (12) months from date of shipment when stored at 25°C in original unopened packages.

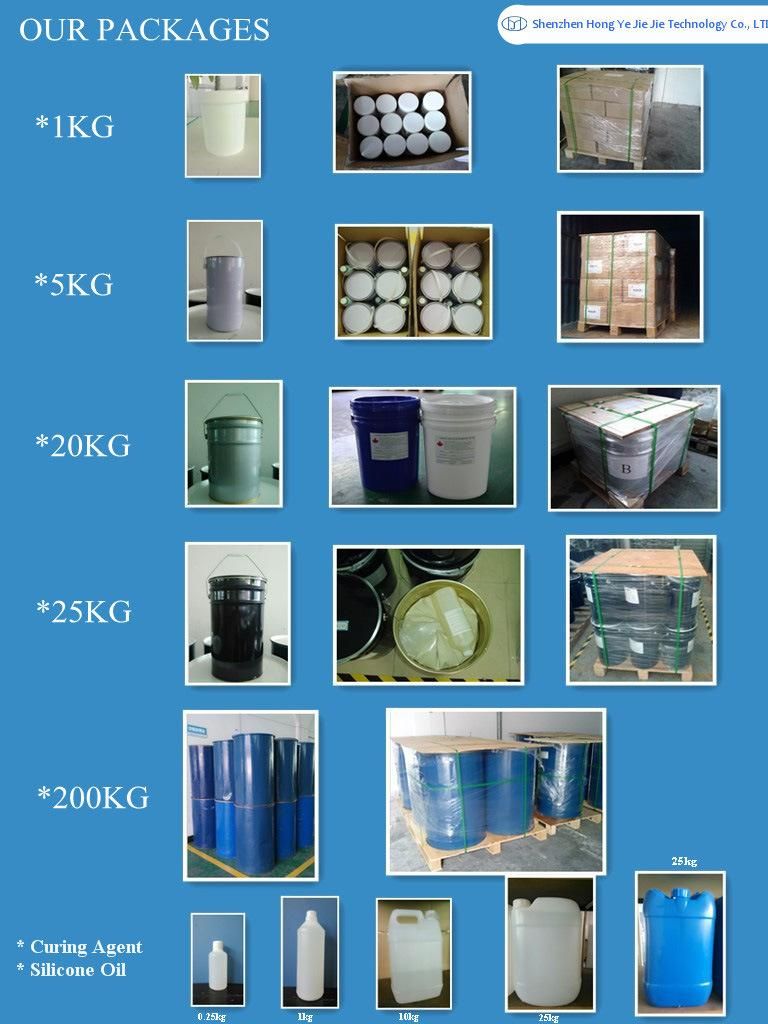

PACKAGE of liquid mouldable silicone:

Packed in clean 1kg/drum, 5kg/drum, 20kg/drum 25kg/drum, 200kg/drum

More information(free sample), pls feel free to contact Ms Lisa: