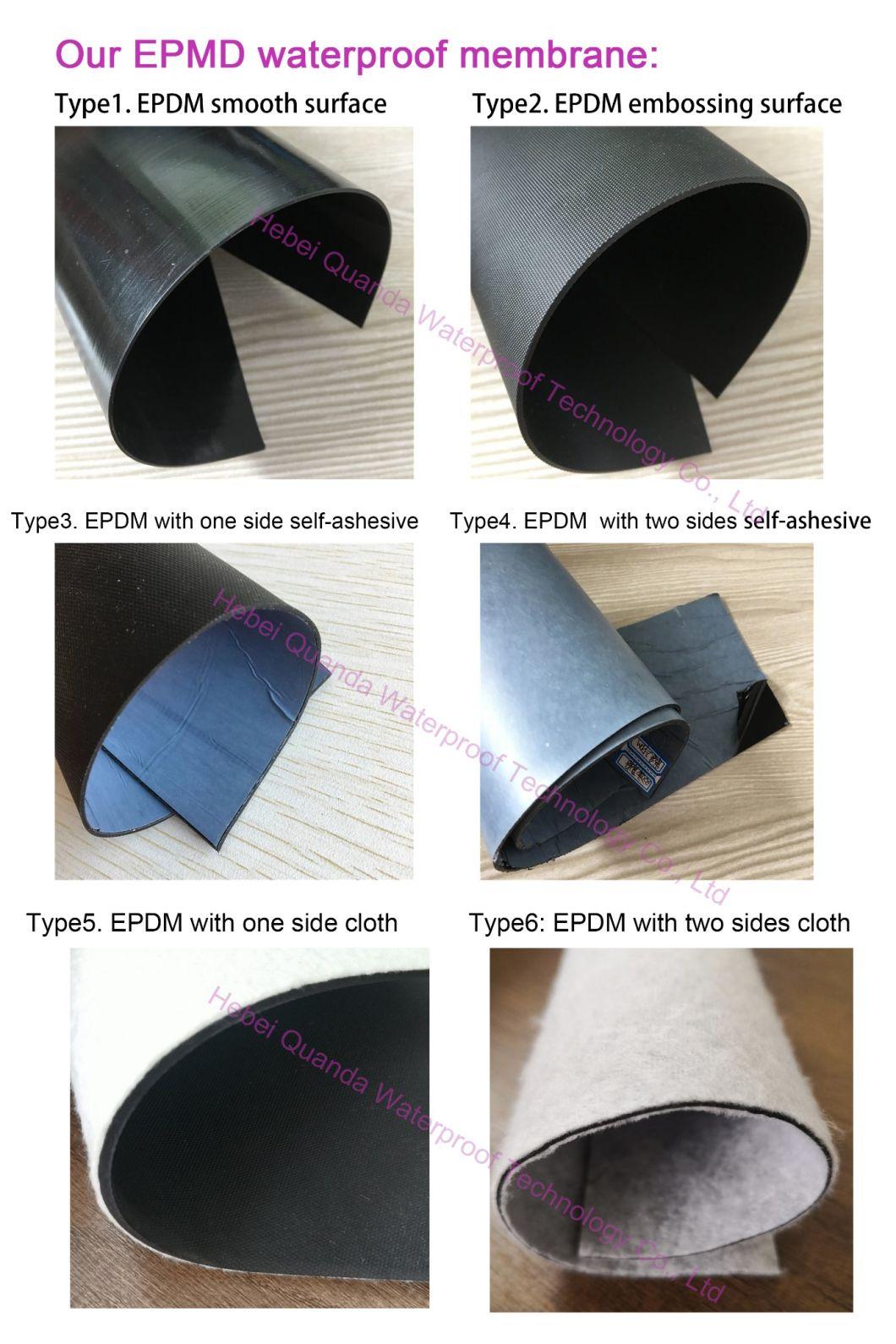

2.0mm EPDM Basement Waterproofing Membrane Waterproof Sheet Building Roof Membrane

Xingshidun New Material Co., Ltd.- Usage:Industrial Rubber Slab, Industrial, Flooring, Printing, Rubber Floor Covering

- Feature:Wear-resistant, Impact-resistant, Heat-resistant, Corrosion-resistant, Insulating, Cold-resistant

Base Info

- Model NO.:EPDM0027

- Raw Materials:EPDM Rubber

- Medium:Pure Gum Rubber Sheet and Fabric

- Performance:Asbestos Rubber Board

- Color:Black Rubber Sheet

- Transport Package:Ocean Ship

- Specification:2.0mm thick

- Trademark:Quanda

- Origin:China

- HS Code:4008210000

- Production Capacity:200000 M2,Day

- Package size per unit product:100.00cm * 12.00cm * 30.00cm

- Gross weight per unit product:35.000kg

Description

dvantage:

1) Good aging resistance, acid and alkali resistance, corrosion resistance, service life up to 50 years.

2) Excellent performance to high and low temperature (-40ºC ~ +100ºC), UV resistant and anti-corrosion.

3) Higher tensile strength and better extensibility, it can better meet the needs of expansion or cracking of the base layer.

4) Easy installation, solid joint, and no environmental pollution.

5) Light weight and reduced roof load.

Application:

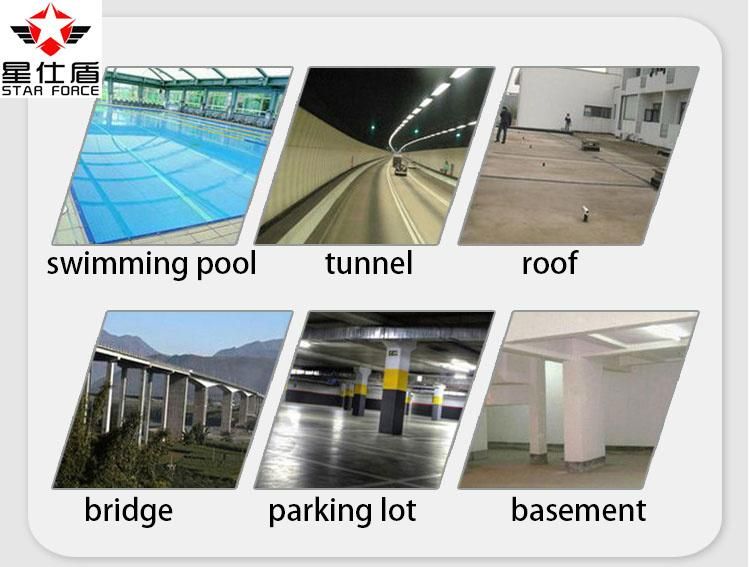

1) Roofs, basement, toilet, bridge, underground, tunnel and dam.

2) Industrial and civil building waterproof.

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially for projects with high requirements in durability, anti-corrosion and deformation.

Construction Method:

1). Ensure all surface are clean,dry and dust-free. Remove any loose particles and any rust with a wire brush & soft broom.

2).Roll out the membrane.

3).Remove the backing paper and place the adhesive side to the previously prepared surface.

4).To ensure a tight contact-smooth the tape down with a dry cloth, remocing all the air bubbles;

5).Press the tape to the surface firmly once in position.

6).Smooth flat all edages with a wallpaper roller or trowel.

7).After use reseal pack and store upright in cool,dry condition.

Storage and Transportation:

1) Waterproof materials should be stored under dry and ventilated conditions.

2) Different types of membranes must be piled separately.

3) Under usual condition, storage period is one year since production date.

4) Waterproof materials should be put vertically during transportation.

5) It should be kept away from sunshine and rainwater.

6) Transport and storage process should be away from the fire source, storage temperature does not exceed 35 ºC, the storage period is 1 year.