Custom or Standard Size Silicone Rubber Gasket Sealing O Ring for Faucets Rubber Seal Shower Head

Qingdao JinYuan Rubber Co.,Ltd.- Material:Silicone Rubber

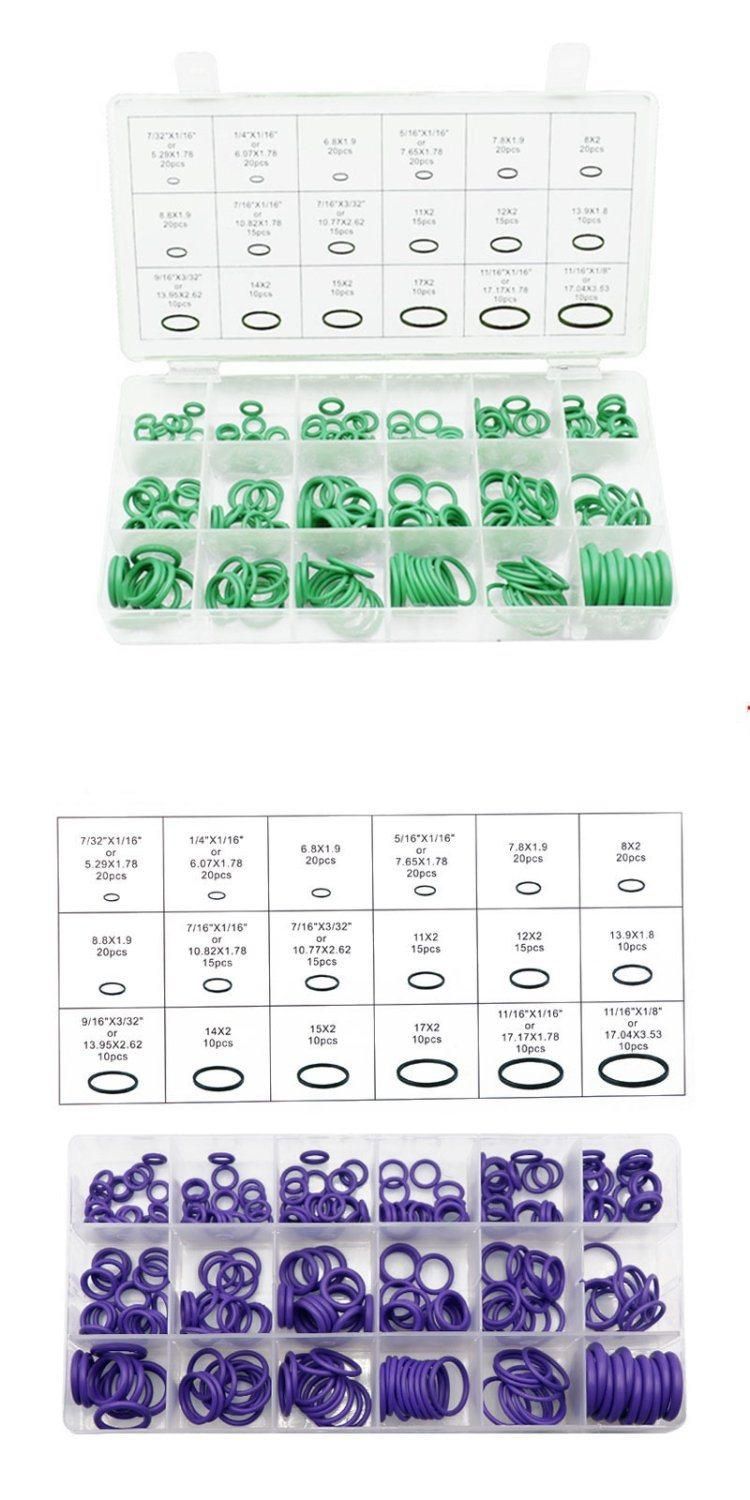

- Application:Machinery, Industrial Component, Electronic Product, Vehicle, Household Appliance, Cylinder, Automobile, Valve, Household, Electrical

- Effect:Fixture&Sealing

- Cross-Section Shape:O-Rings

- Part Name:O Ring

- More Materials:NBR, EPDM, PUR, Silicone, FKM, HNBR, Fvmq, Nr

Base Info

- Model NO.:Rubber Part-JYS009

- Performance:High Temperature, Wear, Corrosion, Oil Resistant

- Shape:Flat, O, D, Y, V, Custom Made

- Function:Fixture and Sealing

- Certificate:RoHS, Reach

- Hardness:30-90 Shore a

- Tensile Strength:>=18MPa

- Elongation at Break:>=360%

- Creep:16%

- Color:All Follows Pantone and Ral Code

- Surface Finish:Texture, Polished, Smooth, Painting

- OEM/OEM:Yes

- Quality Certification:ISO 90001:2008, Ts16949, FDA, Reach, RoHS, SGS

- Part Regulations:BS, JIS, DIN, JIS and ASTM

- Transport Package:Inner Plastic Bag and Cardboard Cartons Outside

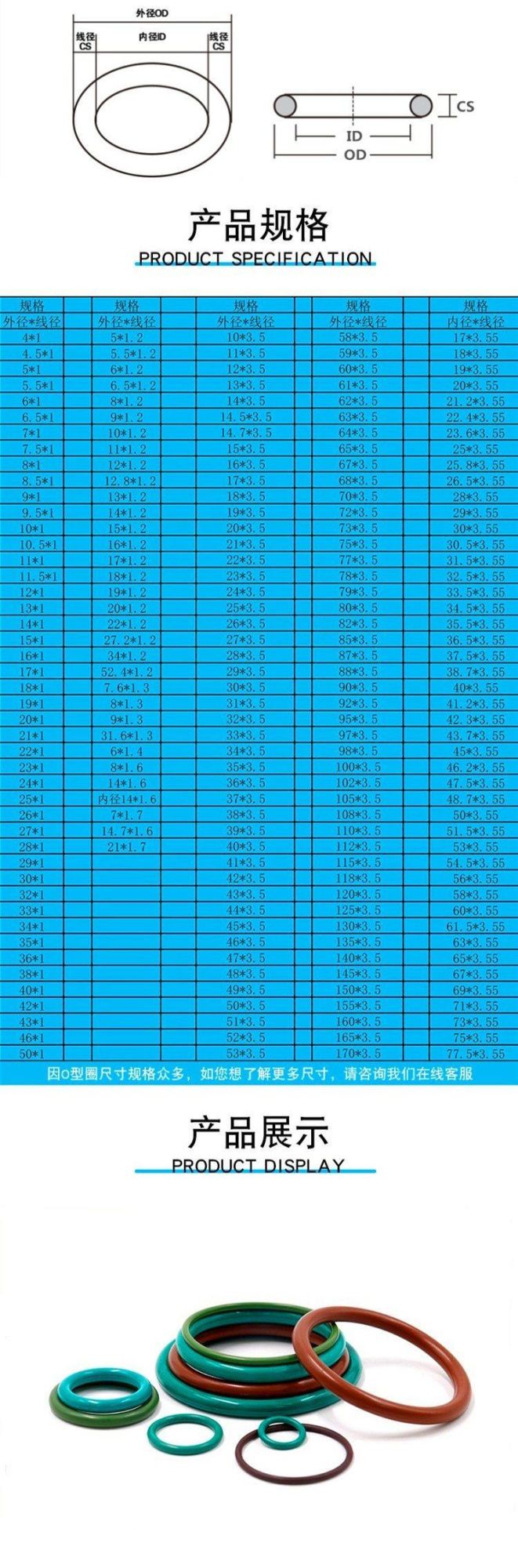

- Specification:Custom dimensions available

- Trademark:OEM, ODM, Jinyuan Rubber

- Origin:China

- HS Code:4016931000

- Production Capacity:1200000 Pieces,Month

Description

O-ring is an O-shaped (circular) annular gasket with cross section. It is generally installed in the groove to make it moderately compressed. It is used as a seal for various fluids such as oil, water, air and so on. There are two uses: fixed use and sports use. If they do not meet the service conditions, problems such as cutting, swelling, compression crack and so on will occur. In order to maintain the sealing performance without deformation for a long time, the materials and dimensions that meet the service conditions must be selected.

Supplying Standard and Customized Rubber & Plastic Parts

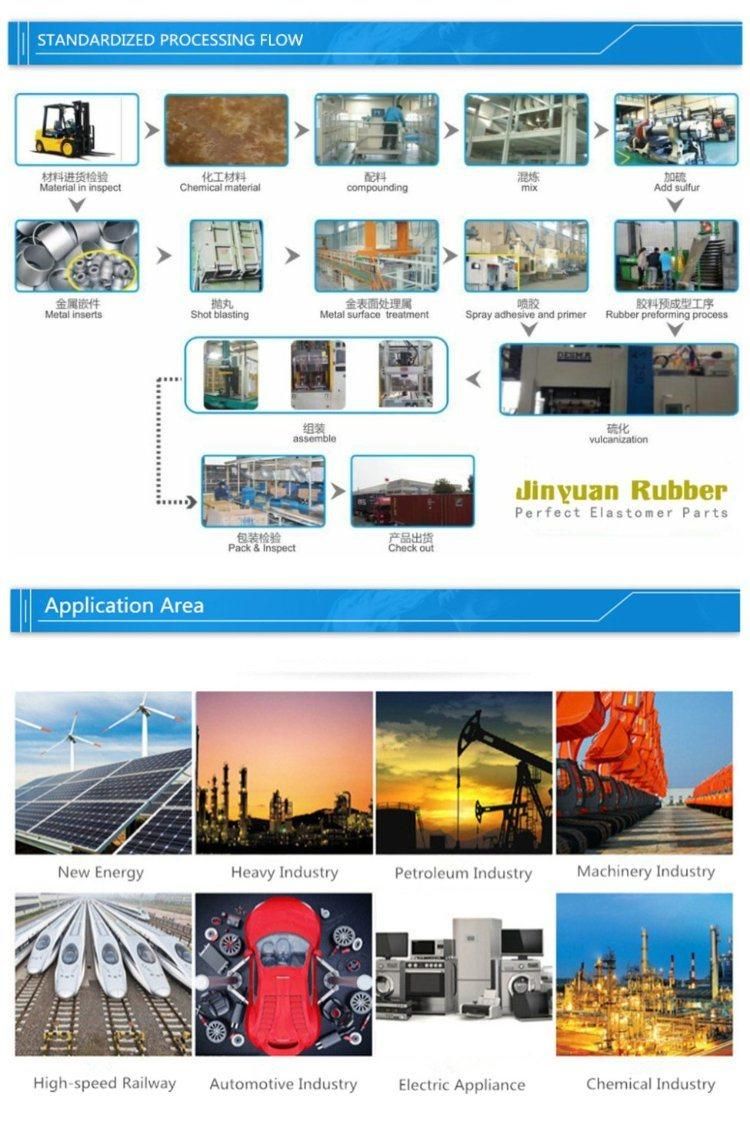

Established in 2004, Jinyuan Rubber is specialized in providing quality customized rubber molding,

extrusion parts, plastic injection products and some standard parts.

Meeting Various Standards

We have a fully-equipped workshop that meets ISO 9001:2015 and IATF 16949:2016 requirements.

Our products are compliant with FDA, WRAS, UL, RoHS and REACH standards, and meet DIN, JIS

, BS and ASTM regulations.

Parts include, but are not limited to:

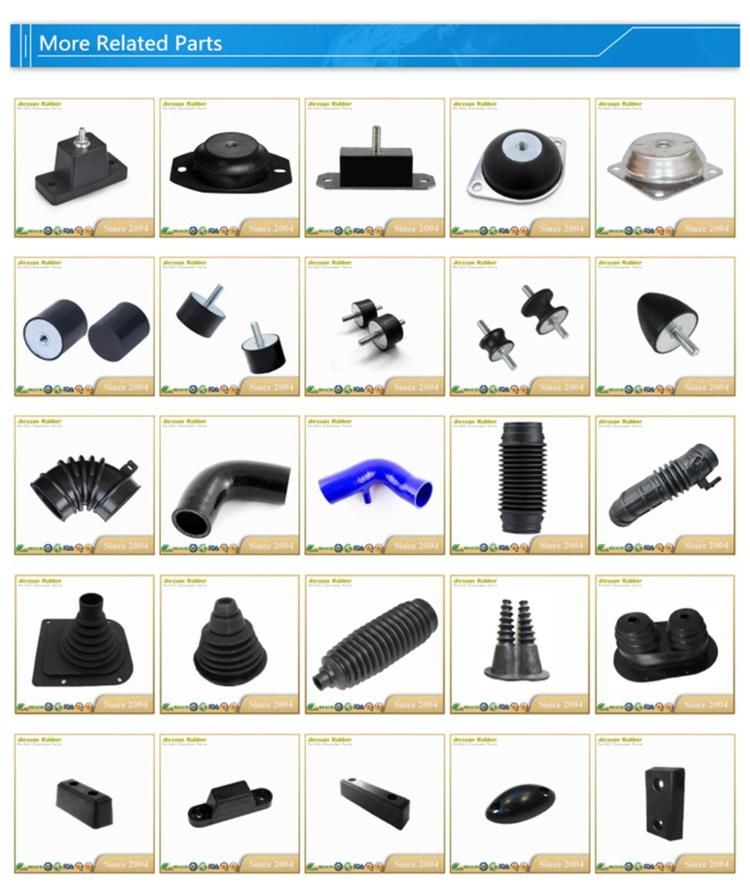

Grommet, sleeve, feet, gasket, wheel, bellow, cap, dust cover, pad, washer, Strip, plug, stopper, grip,

seal, bushing, bumper, blocks, and anti vibration mounts etc.

FAQ

1. What types of rubber do you use?

Jinyuan Rubber has extensive experience in a vast range of rubber, including: Natural Rubber, SBR, CR, NBR, HNBR,

EPDM, Silicone Rubber, FPM, ACM, FK etc.

2. What types of plastic do you use?

Jinyuan Rubber has extensive experience in a vast range of plastics, including: ABS, Polypropylene (PP), PVC, POM,

PE, PEEK, Polyamide (PA) Nylons, PBT, etc.

3. What services do you provide?

We offer a broad range of services, including, Custom Rubber Molding, Liquid Injection Molding, Rubber Extrusion, and

Rubber/Plastic to Metal Bonded Parts.

4. Why us?

4.1 More than 15 years professional manufacture experience.

4.2 Professional R&D team, production team, sales team, after-sales service team.

4.3 Superior performance with most competitive price.

4.4 Faster delivery time.

5. Perfect quality control process

5.1 Raw material inspection

All raw materials before warehousing must be tested, and the corresponding physical property report shall be issued,

and compared with the physical property report of raw materials. Only when the test values of the two physical property

reports are consistent, can they be warehoused.

5.2 Mold inspection

After mold development or cleaning, we will check the full size of the mold to ensure that the quality of each cavity is

the same.

5.3 Product inspection

In the process of product production, inspectors regularly inspect the semi-finished products to ensure the rationality

of the process and control the defective rate within a reasonable range.

5.4 Finished product inspection

The double inspection can ensure that the product appearance and size are 100% qualified.