Air Condition Part Thermal Insulation Material Fireproof Polyethylene Foam

Cyg Tefa Co., Ltd.- Material:PE

- Usage:Air Conditional Thermal Insulation

- Feature:Wear-resistant, Impact-resistant, Heat-resistant, Corrosion-resistant, Insulating, Cold-resistant

- Raw Materials:LDPE

- Medium:AC Foaming

- Performance:Heat Insulation,Waterproof

Base Info

- Model NO.:PE foam for Air Condition Part

- Color:Any Color

- Transport Package:Customized

- Specification:customized

- Trademark:CYG

- Origin:China

- HS Code:3921199000

- Production Capacity:6000 Tons Per Year

Description

Description

Normal size: 1.2m width x 30m Length

Thickness: 3-25mm

Length and width can be customized.,Max width is 1.6m

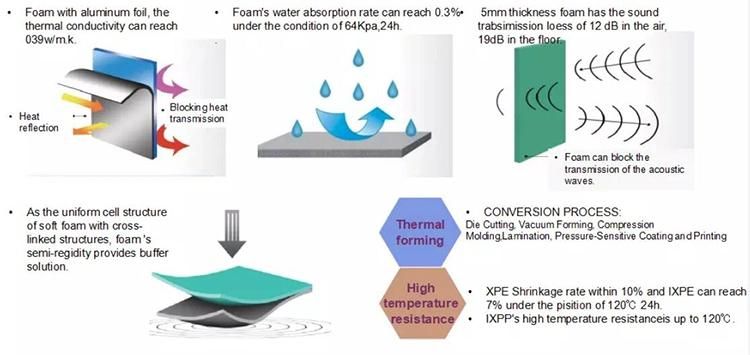

R-Value0.1~0.7 m²K/WDensity33 kg/m³Thermal Conductivity(ASTM C518)0.0409 W/m²KReflectivity (AS/NZS 421.5)95%-97%Flammability Index1Emissivity (AS/NZS 4201.5)0.05Edge Tearing Resistance(AS/NZS 4201.2)432NFoam ColorWhite, Black, Blue

Material structure

1. Al + XPE

2. Al + XPE + Al

3. Al + XPE + Peel&Stick

4. Al+ Woven + XPE + Al

5. Coating + Reinforced Al + XPE + Reinforced Al+ Coating

XPE foam can be fire retardant.

Aluminum foil can be color coating and anti-glare coating.

Aluminum foil can be reinforced fiberglass and woven fabric.

Performance

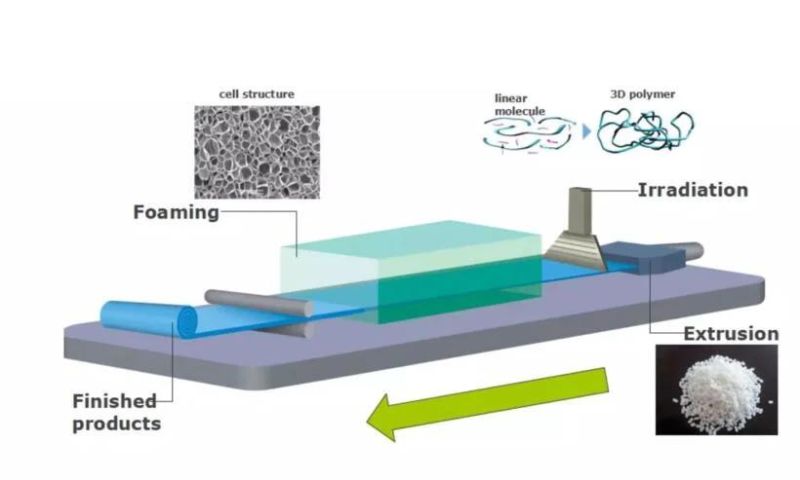

Production

About CYG

CYG TEFA Co., Ltd has 17 years of production experience. We're the biggest and the most professional irradiation cross-linked polyethylene conductive foam manufacturer in China and has the most complete cross-linked polyethylene foam products. Our main products are Cross-linked PE foam material, IXPE foam, XPE foam, Conductive IXPE foam; ESD foam tray, ESD packing material; Beach mat, camping mat, sleeping mat, yoga mat; etc. Our clients are iPhone, Samsung, Gree, Haier, TCL, Adidas, Flextronics, General Motors, BYD, PPL, etc. Now, we have 2 factories and 17 production lines...

Application

Heat insulation and light light inflecting in construction and protection for both cold water and hot water pipe.

Separetion of refrigerator, warm keeping for center air-conditioner, refrigeratory and other home

appliances.

Thermal insulation, sound absorption and noise reduction for car, train, refrigerator car and laboratory, moisture proof cushion for traveling.

Packing for special products and cold storage

It can be made into different colors and anti-static according to customers' specific requirements to reach the standards of top grade decoration

FQA

1) What is closed-cell?

Polyethylene foam is closed-cell, meaning it consists of cells so tightly packed together that it gives the appearance of one uniform structure.

The reality is that the individual cells within polyethylene foam do not physically connect to one another.

This cellular formation is similar to fish caught in a fisherman's net.

2) Why choose Low-density polyethylene foam?

Low-density polyethylene foam has numerous applications because of its many desirable properties including water-resistance, chemical resistance, energy-absorbance, buoyancy and cushioning characteristics. Compressive strength is greater in denser foams, decreasing as density decreases. Low-density foams tend to exhibit more compressive creep, meaning they become less thick over time than higher-density foams.

3) How can I know the suitable foam density I need?

Our PE foam density is between 25 kg/m3 and 240 kg/m3

We can provide the best solution for you according to the application, Density, hardness, thickness.And The free sample is available for your confirmation and text