American As568 Standard Viton/Nitrile Rubber O-Ring

Guangzhou Morgan Seals Co., Ltd.- Material:NBR,Viton,EPDM,Silicone Rubber or Customized

- Application:Machinery, Industrial Component, Electronic Product, Vehicle, Household Appliance

- Effect:Fixture&Sealing

- Cross-Section Shape:O-Rings

- Certificate:ISO 9001:2008

- OEM/ODM:Yes

Base Info

- Model NO.:AS568

- Production Period:Within 30 Days

- Color and Dimension:Accept Customized Products

- Transport Package:Carton,Bag

- Specification:AS568

- Trademark:morgan

- Origin:China

- HS Code:4016931000

- Production Capacity:1000000PCS,Month

Description

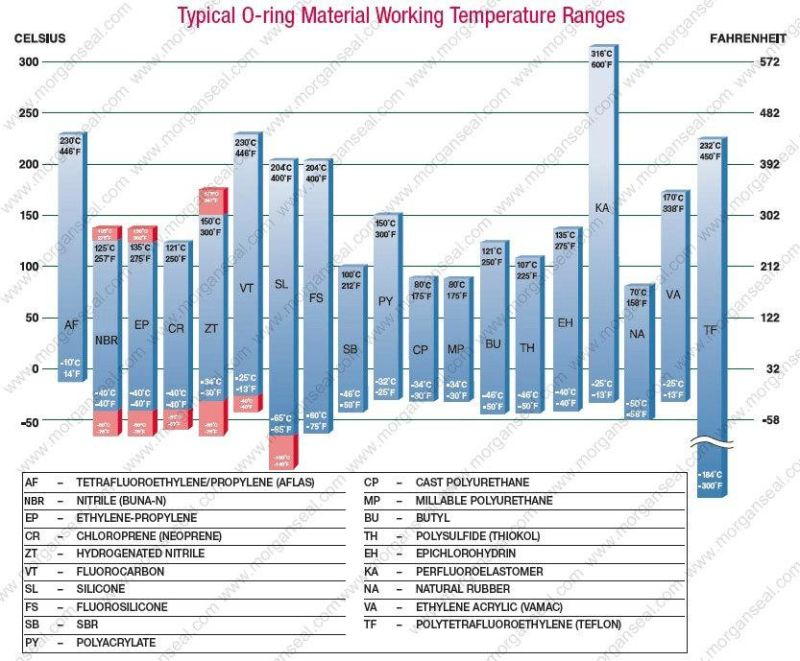

Materials

Morgan O-rings Material Includes Nitrile rubber, fluorine rubber, ethylene propylene rubber, neoprene, chloroprene rubber, silicone rubber and so on.

NBR (Nitrile Butadiene Rubber)

Nitrile rubber (NBR) is the general term for acrylonitrile-butadiene copolymer. The ACN content can vary between 18% and 50%. While the acrylonitrile content is important, the resistance to oil and fuel is more so. Conversely, the elasticity and compression set are not as good. The NBR has good mechanical properties and good wear resistance. However, its resistance to atmospheric agents and the ozone is relatively low.

Mineral oils and greases

Fire-resistant fluids (HFA, HFB and HFC)

Diluted acids, alkaline and saline solutions for low temperatures

Water (up to +100°C max)

Aromatic hydrocarbons

Chlorinated hydrocarbons (trichlorethylene)

Polar solvents (ketone, acetone, acetic acid, ethylene-ester)

Strong acids

Glycol-based brake fluids

Atmospheric and ozone agents

-40°C / +100°C with special NBRs

Fire-resistant liquids (HFD)

Silicone oils and greases

Mineral and vegetable oils and greases

Aliphatic hydrocarbons (propane, butane, petroleum)

Aromatic hydrocarbons (benzene, toluene)

Chlorinated hydrocarbons (trichlorethylene)

Petrol (including high alcohol content)

Atmospheric and ozone agents

Ammoniac gas

Organic acids with a low molecular weight (formic and acetic acids)

-40°C / +200°C with special FKMs

Glycol-based brake fluids (Dot 3 & 4) and silicone-based brake fluids (Dot 5)

Organic and inorganic acids

Cleaning agents, sodium and potassium alkalis

Hydraulic fluids (HFD-R)

Silicone oils and greases

Polar solvents (alcohols, ketones and esters)

Atmospheric and ozone agents

Hydrocarbons

Low impermeability to gas

Mineral and vegetable oils and greases

Fire-resistant fluids (HFA, HFB and HFC)

Diluted acids, saline solutions and bases for low temperatures

Water and steam up to +150°C

Atmospheric and ozone agents

Polar solvents (ketones, esters and ethers)

Strong acids

-40°C / +150°C with special HNBRs

Moderate water temperature

Diluted saline solutions

Atmospheric and ozone agents

Chlorinated hydrocarbons with a low molecular weight (trichlorethylene)

Aromatic hydrocarbons (benzene, toluene)

Fuels

Aromatic hydrocarbons with a low molecular weight (benzene, toluene)

Atmospheric and ozone agents

Aromatic and chlorinated hydrocarbons

Water and steam

Acids, alkalis and amines

-35°C / +150°C with special ACMs

Aggressive mineral oils

Atmospheric agents

Water

Strong acids

Brake fluids

Gearbox oils

ATF oils

Silicone oils and greases

Water and water-based solvents for use at low temperatures

Refrigerant fluids

Ammoniac

Carbon dioxide

Atmospheric and ozone agents

Aliphatic hydrocarbons (propane, butane, petroleum)

Glycol-based brake fluids

Chlorinated hydrocarbons (trichlorethylene)

Polar solvents (ketone, acetone, acetic acid and ethylene-ester)

Polar solvents (ketones, esters, ethers)

Organic and inorganic acids

Water and steam

High-vacuum systems

PFPE

Chemical compatibility

A "Chemical compatibility guide" catalogue can be downloaded from the Literature section. You can also use our online "Chemical compatibility" tool free of charge.

These two tools enable you to measure the behaviour of our materials that come into contact with the majority of existing fluids. The data displayed is the result of rigorous testing at the ambient temperature and takes previous publications into consideration. Test results are not fully representative because of the specific features of your application. The tests performed actually do not consider additives and impurities that may exist under actual conditions of use, nor the potential elevation of temperatures. Other parameters can also alter the behaviour of our materials, such as the hardness, persistence, abrasion, etc. We therefore recommend performing your own tests to verify the compatibility of our materials depending on your specific application. Our technical team can provide you with any additional information.

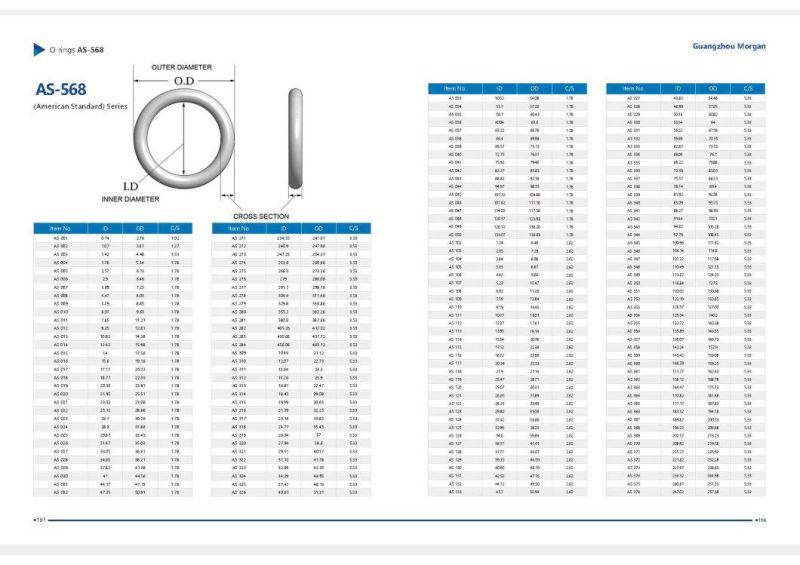

o-ring sizes:

Guangzhou Morgan Seals Co., Ltd. has the biggest vulcanizing machine(4000T) and different kinds of seal moulds. So for the non-standard o ring, oil seals, hydraulic seals, please do not hesitate to contact with us. The following is the the picture Morgan Production Line and Warehouse

Our services:

Guangzhou Morgan Seals Co., Ltd the expert in sealing solution field who combines the rich seals research and production experience of her parent firm with the advanced technology and administration of Morgan, Worcester. Morgan Seals Research and Development ability is based on her parent firm who has won awards as scientific research achievements for more than 1000 projects and over 200 of them won scientific and technological progress prizes of municipal, provincial, ministerial and national levels. At the same time, it also has one National Certified Laboratory, one National Engineering Research Centers and three Industry Level Inspection Centers.