Colored Silicone Good Elongation Sponge Rubber Ball for Pipe Cleaning

SHANGRAO RUICHEN SEALING CO., LTD.- Material:Silicone, NBR, SBR, Nr, HNBR, Acm, EPDM, Iir, Ep

- Application:Machinery, Industrial Component, Machinery, Minerals, Food Processing, Pharmaceut

- Effect:Pipe Cleaning

- Cross-Section Shape:O-Rings

- Size:Based on Your Needs

- Color:Any Color Is Available

Base Info

- Model NO.:various

- Hardness:30~90shore or Irhd

- Research&Design:Impeccable Research and Design

- Transport Package:Plastic Bag or According to Your Request

- Specification:FDA, REACH, RoHS, SGS, etc.

- Trademark:ORK

- Origin:Dongguan, Guangdong, China

- HS Code:4002119000

- Production Capacity:500000PCS,Month

Description

Basic Info.

Model NO. various Hardness 30~90shore or Irhd Research&Design Impeccable Research and Design Transport Package Plastic Bag or According to Your Request Specification FDA, REACH, RoHS, SGS, etc. Trademark ORK Origin Dongguan, Guangdong, China HS Code 4002119000 Production Capacity 500000PCS/MonthProduct Description

Colored Silicone Good Elongation Sponge Rubber Ball for Pipe Cleaning

Material DescrIption for silicone Sponge Rubber Ball

Silicone Rubber (Q, MQ, VMQ, PVMQ)

*Service TemperatureFor Silicones the service temperatures are from -60 C to 225 C. Some special types can be used in extreme temperature up to 300 C and down to -100 C.

*Application

Silicone rubber performs well under environmental and temperature extremes. It is usually applied in automotive and aerospace industries where flexibility and longevity are important. It is also a suitable material for parts that need FDA approval for food handling equipment and appliances.

Product Introduction for Sponge Rubber Ball

Sponge Rubber Ball is especially suitable for various condenser copper tubes. Sponge Rubber Ball is also the most commonly used in power plants. Sponge Rubber Ball is always made of natural rubber with foam and special additives. Standard Sponge Rubber Ball can be used in all kinds of equipment and water .

Sponge Rubber Ball is very effectively in removing biofouling and high viscosity biofouling. Sponge Rubber Ball is Suitable for stainless steel tubes and titanium alloy tube heat exchangers.

The standard appearance of Sponge Rubber Ball

1. The air holes spread evenly on the surface of Sponge Rubber Ball ,and their size is basically similar ;

2, The depth of lack of rubber is less than 3mm on the surface of Sponge Rubber Ball .and the total area of lack of rubber is 10% less than the outside surface area;

3. The diameter tolerance of the sponge rubber ball is ±0.5mm;

Physical properties

After soaking in 40 ± 1 ° C water for 48 hours , the wet density changes from 0.90 to 1.20 g/cm 3 . and the diameter change rate does not exceed 10% of the sponge rubber ball diameter.

In addition, after soaking in water for a period of time, individual rubber balls may swell too much, causing the diameter to exceed the standard,these balls should be replaced in case the tube is blocked

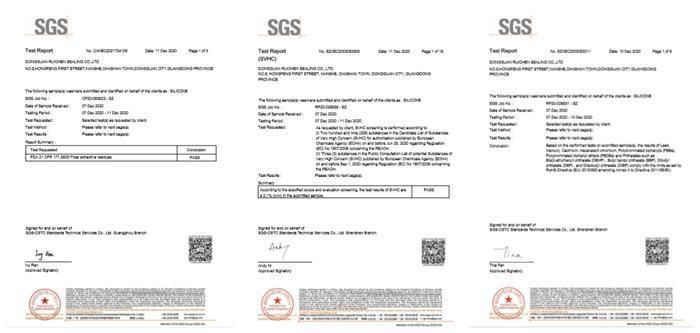

Our product have passed ISO9001 & IATF16949 , FDA ,REACH ,ROHS ,UL certificate

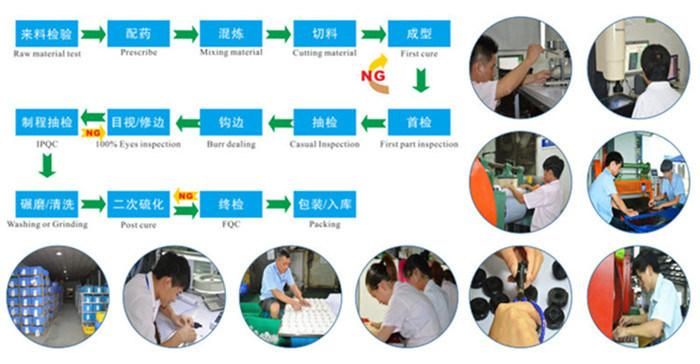

our product progress

our all rubber product are produced according to the below steps .

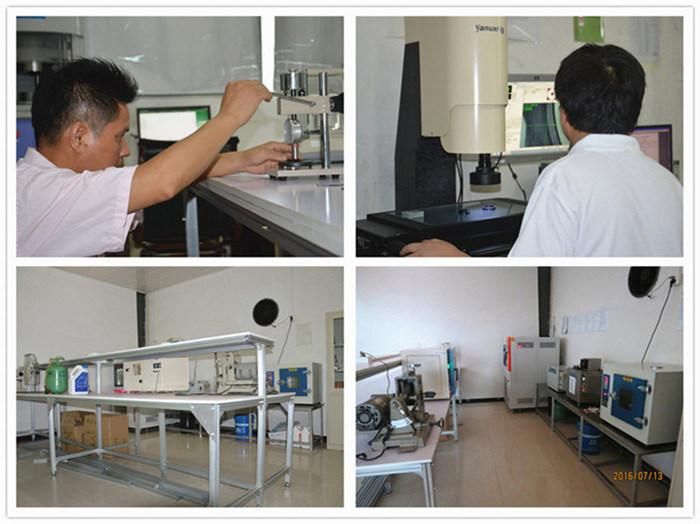

Quality control

Material Inspection:Storage of all raw materials before the test, and issue a report on the corresponding material properties, compared with raw material's own property report, two reports property values is consistent, can put in storage.

Model Inspection:After the mold development or mold cleaning finished on the machine, we will test all the specifications of the mold to ensure that each cavity of the product specifications and quality.

Production Inspection:The production process of the product inspection personnel timing semi-finished product inspection, ensure the quality of the rationality of technology, defective rate control in a reasonable range.

Quanlity Control:The quality inspection department will conduct a sampling inspection of each batch of products

Production Full Inspection:The optical inspection machine can ensure the appearance and dimension of the product are 100% qualified.

Process Flow:

Raw material test → Prescribe → Mixing Material → Cutting Material → First Cure → First Part Inspection → Casual Inspection → Burr Dealing → Eye Inspection → IPQC → Washing or Grinding → Post Cure → FQC → Packing

Packing & Delivery:

Packing: PE bag inside, Carton outside.

Carton size: 46cm*34cm*34cm,40cm*34cn*34cm 51cm*34cm*34cm, 29cm*23cm*19cm

Delivery: Large quantity by ship, small quantity by air or express.

FAQ:

1,Are you manufacture or trading company ?

We are manufacture, we have two factories, one located in Shangrao City, Jiangxi Province, one in Dongguan City, Guangdong Province

2,Can I get samples from you ?

Of course, you can. If the samples you need we have in stock, you can get them for free,

only need to pay for the express cost.

3,What's the term of payment ?

Amount < US$2000, 100% paid in advance by paypal or T/T;

Amount >= US$2000, 30% paid in advance, 70% balance before shipment by T/T.

4,Can you produce OEM products ?

Yes, we can produce products by your drawing or samples.

5,What's your MOQ ?

If we have the products in stock , the quantity by your requirement, If we don't have them in stock:

NBR, SIL, SBR, EPDM, NR: 100 US$; PU, HNBR, FKM: 150 US$

If you clearly display above information,please send an inquiry to 18024335328; or mail to shadow zhang, we will reply to you as soon as possible! Thank you!