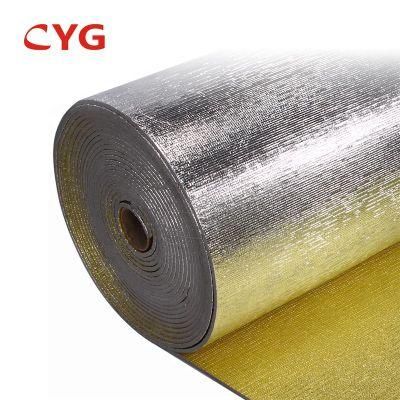

Aluminum Foil Insulation Heat Resistant Foam

Cyg Tefa Co., Ltd.- Material:PE

- Usage:Roof

- Feature:Wear-resistant, Heat-resistant, Corrosion-resistant, Insulating, Cold-resistant

- Raw Materials:LDPE

- Performance:Insulating Rubber Slab

- Color:Any Color

Base Info

- Model NO.:IXPE

- Transport Package:Poly Bags

- Specification:customized

- Trademark:CYG

- Origin:China

- HS Code:3921199000

- Production Capacity:1000000m Per Month

Description

Product SpecFoam type IXPE foam Material Low density PE foam Foam density 33-100kg/m3 Thickness 1mm/1.2mm/2mm/3mm Color Black/Blue/Green /Orange etc IIC(Impact Insulation Glass) 60-64db STC(field Impact Insulation Class) 58-66db Support Customization Hole punch ,Aluminum foil ,PE film coating

FQA

1) What is closed-cell?

A: Polyethylene foam is closed-cell, meaning it consists of cells so tightly packed together that it gives the appearance of one uniform structure.

The reality is that the individual cells within polyethylene foam do not physically connect to one another.

This cellular formation is similar to fish caught in a fisherman's net.

2) Why choose Low-density polyethylene foam?

A: Low-density polyethylene foam has numerous applications because of its many desirable properties including water-resistance, chemical resistance, energy-absorbance, buoyancy and cushioning characteristics. Compressive strength is greater in denser foams, decreasing as density decreases. Low-density foams tend to exhibit more compressive creep, meaning they become less thick over time than higher-density foams.

3) How can I know the suitable foam density I need?

A: Our PE foam density is between 25 kg/m3 and 240 kg/m3

We can provide the best solution for you according to the application, Density, hardness, thickness.And The free sample is available for your confirmation and text

4) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (ABC bank) and Paypal, Western Union are the most usual ways we are using for freight fees of PE foam samples.

5) What's the order procedure?

A: First we discuss foam products details by email or TM.

Then we issue you a PI for your confirmation. You will be requested to do prepaid full payment or deposit before we go into production.

After we get the deposit, we start to process the order. usually takes 7-15days if we don't have the items in stock.

Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

6) How do you take care when your clients received defective foam products?

A: replacement. If there are some defective foam products, we usually credit to our customer or replace in next shipment.

7) How do you check all PE foam on the production line?

A: We have spot inspection and finished product inspection of our foam materials.We check the PE foam materials when they go into next step production procedure.

8)What is PE foam?

A: Polyethylene foam is a strong, resilient closed-cell foam. Ideally foam material suited as the material or part of a material required in products requiring a shock absorbing, vibration dampening, insulation, barrier or buoyancy component etc.

9) What's the application of insulation?

A: Our insulation products are widely used on roofing, external wall, floor, HVAC pipe, transportation and any other places needing insulation.

Low-density polyethylene foam has numerous applications because of its many desirable properties including water-resistance, chemical resistance, energy-absorbance, buoyancy and cushioning characteristics. Compressive strength is greater in denser foams, decreasing as density decreases. Low-density foams tend to exhibit more compressive creep, meaning they become less thick over time, than higher-density foams.

10) What's the difference between pure aluminum & metallic aluminum(MPET)?

A: Pure aluminum is metal film which can be fireproof, while metallic aluminum(MPET) is just plastic film which can be fire.

FQA

1) What is closed-cell?

A: Polyethylene foam is closed-cell, meaning it consists of cells so tightly packed together that it gives the appearance of one uniform structure.

The reality is that the individual cells within polyethylene foam do not physically connect to one another.

This cellular formation is similar to fish caught in a fisherman's net.

2) Why choose Low-density polyethylene foam?

A: Low-density polyethylene foam has numerous applications because of its many desirable properties including water-resistance, chemical resistance, energy-absorbance, buoyancy and cushioning characteristics. Compressive strength is greater in denser foams, decreasing as density decreases. Low-density foams tend to exhibit more compressive creep, meaning they become less thick over time than higher-density foams.

3) How can I know the suitable foam density I need?

A: Our PE foam density is between 25 kg/m3 and 240 kg/m3

We can provide the best solution for you according to the application, Density, hardness, thickness.And The free sample is available for your confirmation and text

4) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (ABC bank) and Paypal, Western Union are the most usual ways we are using for freight fees of PE foam samples.

5) What's the order procedure?

A: First we discuss foam products details by email or TM.

Then we issue you a PI for your confirmation. You will be requested to do prepaid full payment or deposit before we go into production.

After we get the deposit, we start to process the order. usually takes 7-15days if we don't have the items in stock.

Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

6) How do you take care when your clients received defective foam products?

A: replacement. If there are some defective foam products, we usually credit to our customer or replace in next shipment.

7) How do you check all PE foam on the production line?

A: We have spot inspection and finished product inspection of our foam materials.We check the PE foam materials when they go into next step production procedure.

8)What is PE foam?

A: Polyethylene foam is a strong, resilient closed-cell foam. Ideally foam material suited as the material or part of a material required in products requiring a shock absorbing, vibration dampening, insulation, barrier or buoyancy component etc.

9) What's the application of insulation?

A: Our insulation products are widely used on roofing, external wall, floor, HVAC pipe, transportation and any other places needing insulation.

Low-density polyethylene foam has numerous applications because of its many desirable properties including water-resistance, chemical resistance, energy-absorbance, buoyancy and cushioning characteristics. Compressive strength is greater in denser foams, decreasing as density decreases. Low-density foams tend to exhibit more compressive creep, meaning they become less thick over time, than higher-density foams.

10) What's the difference between pure aluminum & metallic aluminum(MPET)?

A: Pure aluminum is metal film which can be fireproof, while metallic aluminum(MPET) is just plastic film which can be fire.