Rubber Oring Sealing and EPDM Vs Buna O-Ring Manufacturer

Xiamen Yiho Polytek Co., Ltd.- Material:Nitrile Rubber

- Application:Machinery, Industrial Component, Electronic Product, Vehicle, Household Appliance

- Effect:Fixture&Sealing

- Cross-Section Shape:O-Rings

- Price:Negotiable

- MOQ:10000PCS

Base Info

- Model NO.:YH-EPDM001

- Hardness:30-90 Shore a

- Tolerance of Size:ISO3301-M2 or Your Requirement

- Tolerance of Hardness:+,-5 Shore a

- Color of NBR Oring:Black or Another Pantone Color

- Sample:Freely for You

- Customized:by Your Drawing or Sample

- Catalogue:RoHS,Reach,FDA

- Company:Manufacturer

- Transport Package:Carton Box

- Specification:47*30*27cm

- Trademark:YIHO

- Origin:China

- Production Capacity:50000,PC

Description

Basic Info.

Model NO. YH-EPDM001 Hardness 30-90 Shore a Tolerance of Size ISO3301-M2 or Your Requirement Tolerance of Hardness +/-5 Shore a Color of NBR Oring Black or Another Pantone Color Sample Freely for You Customized by Your Drawing or Sample Catalogue RoHS/Reach/FDA Company Manufacturer Transport Package Carton Box Specification 47*30*27cm Trademark YIHO Origin China Production Capacity 50000/PCProduct Description

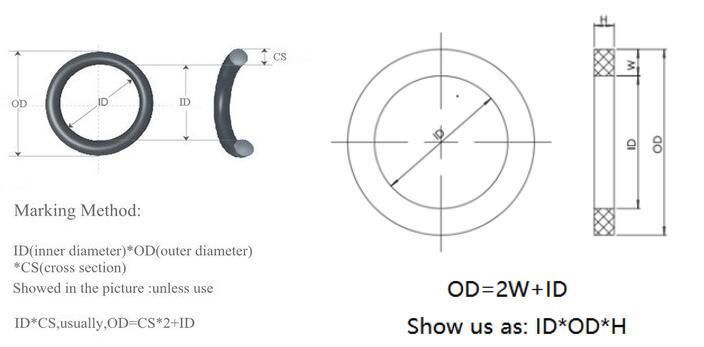

rubber oring sealing and epdm vs buna o-ring manufacturer

Rubber epdm vs buna o-ring selection is based on chemical compatibility, application temperature, sealing pressure, durometer, size and cost. These parameters will determine the best suited material for an application. O-rings are available in several different materials such as PTFE, Nitrile (Buna), Neoprene, EPDM Rubber and Fluorocarbon (Viton). Rubber o-rings and Silicone seals are also widely used high temperature applications.

Some information of epdm vs buna o-ring:

1.EPDM (ethylene-propylene-diene-monomer) is a specially designed synthetic rubber for water applications. The general operating temperature for EPDM is -70 to 300 degrees Fahrenheit making it well suited to most water storage applications. In addition to outstanding water resilience, EPDM is very resistant to damage caused by heat, compression, sunlight, acetones, alkalis and ozone. However, it is not recommended for use with acids or hydrocarbons.

2.Buna-N is another option when outstanding resistance to oil, hydrocarbon and chemicals is required. Buna-N tank gaskets are comprised of a synthetic rubber copolymer and are very well suited to storage of crude oil and other petrochemicals. When storing ketones, esters and aldehydes in steel tanks, other gasket material is recommended for better longevity. Buna-N gaskets for steel tanks can withstand lower temperatures ranging from -40 to +212 degrees Fahrenheit.

More parameter of epdm vs buna o-ring

Item | epdm vs buna o-ring |

Color | Black, white, red, green, transparent or any color according to Pantone code |

Size | As per customer's requirements |

Tolerance | ±0.05mm |

Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

Technology | Hot pressing molding, injection molding, extrusion |

Application | Automotive, Mechanical equipment, Construction, Home appliance, Aviation, |

Major Equipments | Laser cutting machine, CNC punching machines, bending machines, welding machines, spot welding machines, stamping machines, pipe cutting machine, powder coating line, etc. |

Advantages | Low cost & Fast Delivery & High quality. |

Certification | ROHS, ,ISO9001,TS16949,Reach |