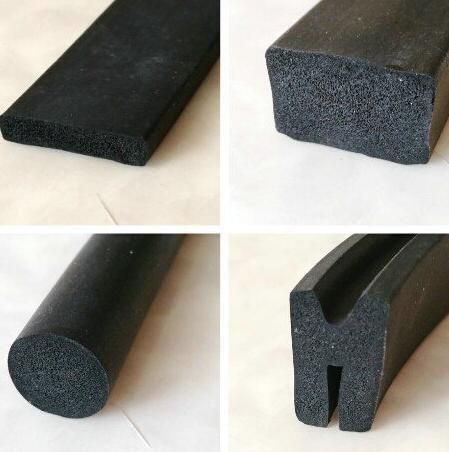

Closed Cell Soft Insulation Sealing Silicone Foam Sponge Cord

Hangzhou Bright Rubber Plastic Product Co., Ltd.- Material:Natural Rubber

- Capability:Water Rubber Hose

- Color:Red, Black

- Shape:According to Drawing

- Hardness:30-90 Shore a

- Tensile Strength:>=17MPa

Base Info

- Model NO.:Custom

- OEM/ODM:Yes

- Transport Package:Inner Polybag with Carton Box

- Specification:customized

- Trademark:None

- Origin:China

- HS Code:4001100000

- Production Capacity:1000000PC,Month

Description

Basic Info.

Model NO. Custom OEM/ODM Yes Transport Package Inner Polybag with Carton Box Specification customized Trademark None Origin China HS Code 4001100000 Production Capacity 1000000PC/MonthProduct Description

Introduction:

The rubber strip cord is made of common material of EPDM/silicone, and a different tape is applied to the back of the sponge rubber strip.it has many advantages, such as excellent weather resistance, aging resistance, ozone resistance, acid and alkali resistance.

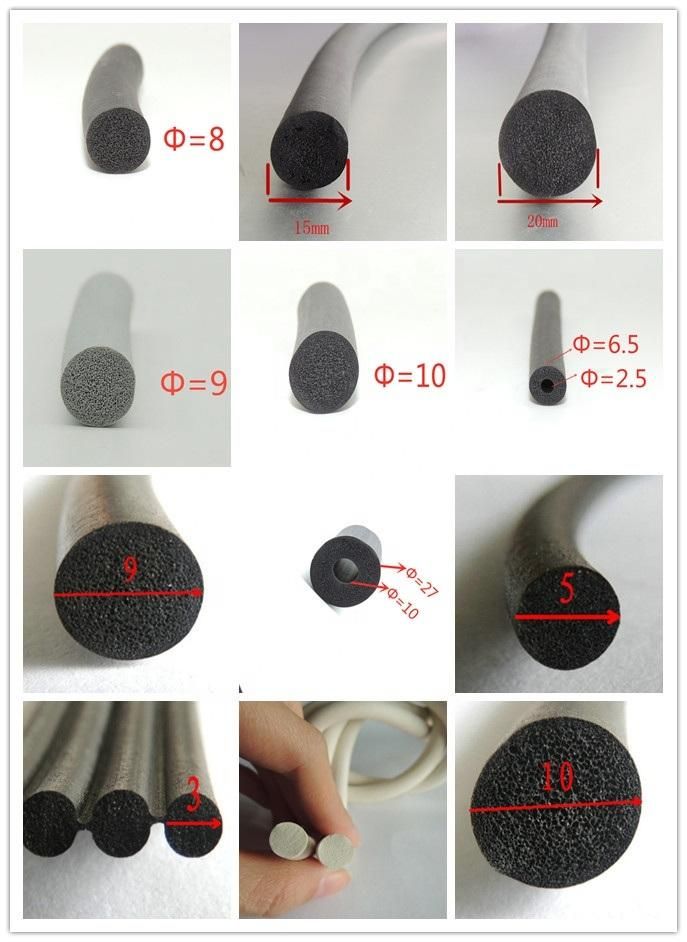

Specification:

Material: sponge rubber/silicone

Type: foam/sponge rubber

Density:from 0.3 to 0.9g/cm3

Handness:10 to 40 Shore A

Color:black or custom

Other related rubber products

FAQ

Q: Are you manufacturer or trading company?

A: We are manufacturer, engineer had rich experience over 20 years.

Q: How to get the quickest quotation?

A: Sending drawing, material, quantity and other rrequirements by email.

Q: How to get quotation without drawing?

A: Possible send sample, pictures or detail descriptions of products to us, we will return you drawing for confirm.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?A. Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Q: My custom products have already been developed on CAD. Can you use the drawings?

A. Yes! DWG, DXF, IGES, Solidworks and Rhino files can all be used to generate quotes, models and mould tools - this can save time and money in producing your parts.

Q: Can I test my idea/product before committing to mould tool manufacture?

A. Yes, we can use CAD drawings to make models for design and functional evaluations.

Q: What type of plastic/rubber material is best for my design/product?

A. Materials selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternatives and suggest the best material.

Q: How to get sample?

A: Free sample is available for your quality evaluation, but you should pay the freight. Regarding customize products, sample and mould order will go first before mass production.