-

Customized Rubber Oil Seal Rubber Seal Gasket Durable

Packaging & DeliveryProducts DescriptionWhy Choose UsFAQQ1. Can I have a sample order?A: Yes, we welcome sample order and it will be free samples for our stock samples to test and check quality. Mixed samples are acceptable.Q2. What about the lead time?A: Stock Sample : 1-3days, mass production

-

O Rings Manufacturer Silicone Rubber O -Ring

Size=ID*OD*C/S,OEM,accoring to customer's request or drawingMaterialPTEF, NBR, SBR, EPDM, FKM, Silicone, HNBR,etc.ColorBlack/White/Blue/Red/Yellow/Grey/Orange, etcTemperatureCommom: -40~230 Celsius DegreesHardnessFrom 20Shore Ato 95Shore AacceptableApplicationUsed in fitting, pipes,machinery,and oth

-

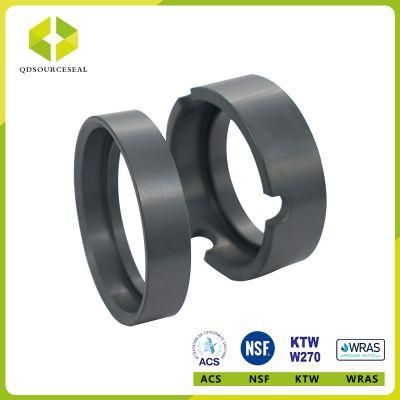

Supply All Kinds of Mechanical Seal/Forklift Oil Seal

SpeciesOilresistanceWeatherresistanceWearresistanceThe lowestTemperatureThe highestTemperatureFeaturesFKMoptimaloptimaloptimal-40250It has excellent heat resistance, oil resistance and chemical resistance, and is the best balanced rubber for oil seal.VMQgoodoptimalgood-60225It has excellent heat res

-

Square Silicone Rubber Feet Furniture Pad Foot for Cushion Vibration Absorber

Basic Info. Trademark YXD O

-

Size=ID*OD*C/S,OEM,accoring to customer's request or drawingMaterialPTEF, NBR, SBR, EPDM, FKM, Silicone, HNBR,etc.ColorBlack/White/Blue/Red/Yellow/Grey/Orange, etcTemperatureCommom: -40~230 Celsius DegreesHardnessFrom 20Shore Ato 95Shore AacceptableApplicationUsed in fitting, pipes,machinery,and oth

-

Compression Molded Nr/NBR/EPDM Rubber Dustproof Cover

Basic Info. Model NO. pk150

-

PVC Slot Type Wooden Door Seal

MaterialSiliconeColorGrey, black, brown, white etc. or other color as your requirementHardness20-70 Shore AFeatures1.Good shockproof, sound insulation and heat insulation performance.2.Good sealing, shock absorption, air insulation, Energy-saving, and anti-insect .3.Beautiful and endurable4.Excellen