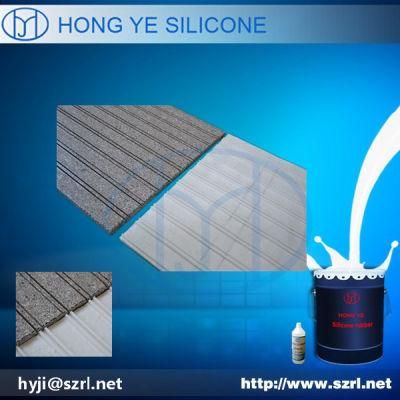

RTV2 Silicone Rubber for Molds Making for Concret, Resin, Gypsum

Shenzhen Hong Ye Jie Technology Co., Ltd.- Raw Material:Mold Making Silicone

- Material:Silicone Rubber

- Appearance:White, Translucent

- Form:Liquid

- Application:Mold Making for Grc, Gyspusm, Resin, Concrete, etc

- Color:as Requested

Base Info

- Model NO.:HY-6 series Silicone Rubber for Molds Making

- Purity:100%

- Molding Method:Pouring , Brushing

- Sample:Free

- Package:Vacuum Packing

- Certificate:FDA, SGS, RoHS, MSDS, ISO9001:2000

- Payment:T,T 100% in Advance, L,C, Western Union

- H.S. Code:39100000

- Shrinkage:Less Than 0.3%

- Transport Package:25kg,drum or 200kg,drum

- Specification:RoHS, SGS, MSDS

- Trademark:Hong Ye silicone rubber

- Origin:China

- HS Code:39100000

- Production Capacity:8 Ton Per Day

Description

Basic Info.

Model NO. HY-6 series Silicone Rubber for Molds Making Purity 100% Molding Method Pouring / Brushing Sample Free Package Vacuum Packing Certificate FDA, SGS, RoHS, MSDS, ISO9001:2000 Payment T/T 100% in Advance, L/C, Western Union H.S. Code 39100000 Shrinkage Less Than 0.3% Transport Package 25kg/drum or 200kg/drum Specification RoHS, SGS, MSDS Trademark Hong Ye silicone rubber Origin China HS Code 39100000 Production Capacity 8 Ton Per DayProduct Description

RTV Silicone Rubber for Molds Making1.Appication for Liquid RTV Silicone Rubber for Molds Making for concret ,resin, gypsum

RTV Silicone Rubber for Molds Making is mainly used in mold making for the manufacturer of products made of unsaturated resin, epoxy resin, polyurethane, cultural relic duplication, architectural decoration, resin crafts, lighting ornaments, candles, statues, model design, product exploitation etc.HY-638 is good for mold making of fine and complex products, HY-788 is good for mold making of large and simple products.

2.Features for RTV Silicone Rubber for Molds Making

(1)With SGS and RoHS approval

(2)Curing agent arrange together as free charged

(3)In liquid form and in various colors

(4)With an exceptional fluidity and good operability.

(5)Temperature and deformation resistance as well as low Shrinkage.

(6)High duplication times.

(7)Samples are available

3.Datasheet for RTV Silicone Rubber for Molds Making

Technical Datasheet:

| Model | HY-625# | HY-630# |

| Color | White | White |

| Mixing ratio (%) | 2-5% | 2-5% |

| Pot life (mins,under 25ºC) | 30-40 | 30-40 |

| Curing time(hrs,under 25ºC ) | 4-5 | 4-5 |

| Hardness ( Shore A ) | 25±2 | 30±2 |

| Viscosity(After A/B mixed ,mPa.S) | 25000±5000 | 27000±5000 |

| Tensile-strength (MPa) | 4.3±0.5 | 3.8±0.5 |

| Tear-strength (kN/m) | 26±2 | 26±2 |

| Shrinkage rate (%) | ≤0.3% | ≤0.3% |

| Elongation(%) | 500% | 480% |

(Note :Other hardness can be provided to your requirements and silicone oil can be also provided to adjust the hardness and viscosity of silicone)

4.Using instruction for Liquid RTV Silicone Rubber for Molds Making for concret ,resin, gypsum

Component A is white flowing liquid and component B is the curing agent.For example, take silicone rubber of 100g and add 2g curing agent for mixing evenly (silicone rubber and curing agent must be measured accurately).After the silicone rubber and the curing agent are completely mixed, put the silicon into a vacuum machine for deairing to remove the bubbles.After deaired, pouring the liquid silicone rubber into the product to be duplicated or into the mold frame.If you don't have vacuum machine, please add 1.2% or 1.5% curing agent so that the bubbles can bubble itself.Since the less curing agent you add, the slower the mould will curdle, the bubbles will bubble out itself.

5.Package for RTV Silicone Rubber for Molds Making

5kg/drum, 25kg/drum, 200kg/drum

Certificate:

ISO900:2000

FDA

SGS

UL

RoHS

REACH

ISO9001:HK05/01358

SGS:GZ0606100461/CHEM

RoHS:BTRS091718751

Patent:ZL200520001597.8

Company Profile of Hong Ye Jie Silicone:

As a Leading manufacturer of liquid silicone rubber with more than 18 years,believed that we really can provide your the high-quality product with Competitive price,and even the technical support and perfect after-sales service.We really hope we can start an cooperation by giving both size chance .You get an chance for figure out an very good supplier ,We get the reputable partner for delevoping our silicone in your country.Let's do something good for your company in the future !