LDPE Thermal Product Insulation Material Cross Linked Polyethylene Foam for Air Hose

Cyg Tefa Co., Ltd.- Feature:Wear-resistant, Impact-resistant, Heat-resistant, Insulating

- Color:Black Rubber Sheet

- Density:28~300kg,M3

- Shore Hardness:13~70 Degree

- Certificate:ISO9001, Reach, RoHS, Iatf16949, Ce

- Structure:Closed Cell

Base Info

- Model NO.:IXPE Foam

- Refractoriness:100-150 Degree

- Thermal Conductivity:0.040~0.095 W,M.K

- Transport Package:Poly Bags

- Specification:customized

- Trademark:CYG

- Origin:China

- HS Code:3921199000

- Production Capacity:1000000m Per Month

Description

WIDTH

Produced in roll form of 1.0M - 1.8M, depending on foam density and thickness.

HICKNESS

Single layer sheeting of 0.5-15mm, and also laminating multiple layers of sheets up to 80mm.

Foam color

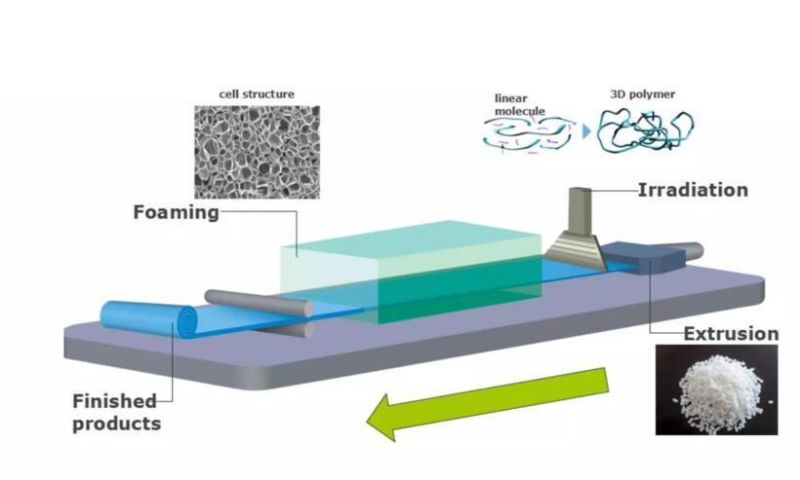

Production

Features

Lightweight

Cost-effective

Easy to fabricate

Extremely low odour

Non toxic

High shock absorption

Flexibility

Polyethylene foam thermal insulation material

Applications

As for automotive air hose,CYG FOAM has many advantages.

1) no smelling, non-toxic: Use ecologic material, RoHS approval

2) soft and comfortable: Flexible with good elastic, stay the shape soon after press

3) dampproof and waterproof: Closed cross linked structure

4) heat insulation: Closed cross linked structure, keep warm

6) light and portable: About 500g/PCS

7) durable: Good elastic and closed cross linked structure

8)Easy processing: Continuous; Easy hot-press shaping, casting, gluing and joining.

9)Shockproof: Good flexibility and anti-hardening; Excellent shockproof and cushion capability.

10)Sound insulation: Closed-cell foam, good sound insulation capability.

About CYG

CYG TEFA Co., Ltd has 17 years of production experience. We're the biggest and the most professional irradiation cross-linked polyethylene conductive foam manufacturer in China and has the most complete cross-linked polyethylene foam products. Our main products are Cross-linked PE foam material, IXPE foam, XPE foam, Conductive IXPE foam; ESD foam tray, ESD packing material; Beach mat, camping mat, sleeping mat, yoga mat; etc.

FQA

1)What is PE foam?

Polyethylene foam is a strong, resilient closed-cell foam. Ideally foam material suited as the material or part of a material required in products requiring a shock absorbing, vibration dampening, insulation, barrier or buoyancy component etc.

2) What's the order procedure?

First we discuss foam products details by email or TM.

Then we issue you a PI for your confirmation. You will be requested to do prepaid full payment or deposit before we go into production.

After we get the deposit, we start to process the order. usually takes 7-15days if we don't have the items in stock.

Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

3) How can I know the suitable foam density I need?

Our PE foam density is between 25 kg/m3 and 240 kg/m3

We can provide the best solution for you according to the application, Density, hardness, thickness.And The free sample is available for your confirmation and text

4) What's the application of insulation?

Our insulation products are widely used on roofing, external wall, floor, HVAC pipe, transportation and any other places needing insulation.

Low-density polyethylene foam has numerous applications because of its many desirable properties including water-resistance, chemical resistance, energy-absorbance, buoyancy and cushioning characteristics. Compressive strength is greater in denser foams, decreasing as density decreases. Low-density foams tend to exhibit more compressive creep, meaning they become less thick over time, than higher-density foams.