Rubber Seal for Wuling Hongguang, Glory, Light, Chevrolet N3001.2/1.5 Crankshaft Rear Oil Seal Assembly 9025144

Ren County Fumeida Machine Parts Co., Ltd.- Application:Machinery, Industrial Component, Electronic Product, Vehicle, Household Appliance

- Effect:Wiper Seal

Base Info

- Model NO.:9025144

- Cross-Section Shape:O-Rings

- Transport Package:Color Boxes and Cartons

- Specification:9025144

- Trademark:FMD

- Origin:China

- Production Capacity:1000000PCS,Year

- Package size per unit product:20.00cm * 10.00cm * 4.00cm

- Gross weight per unit product:1.000kg

Description

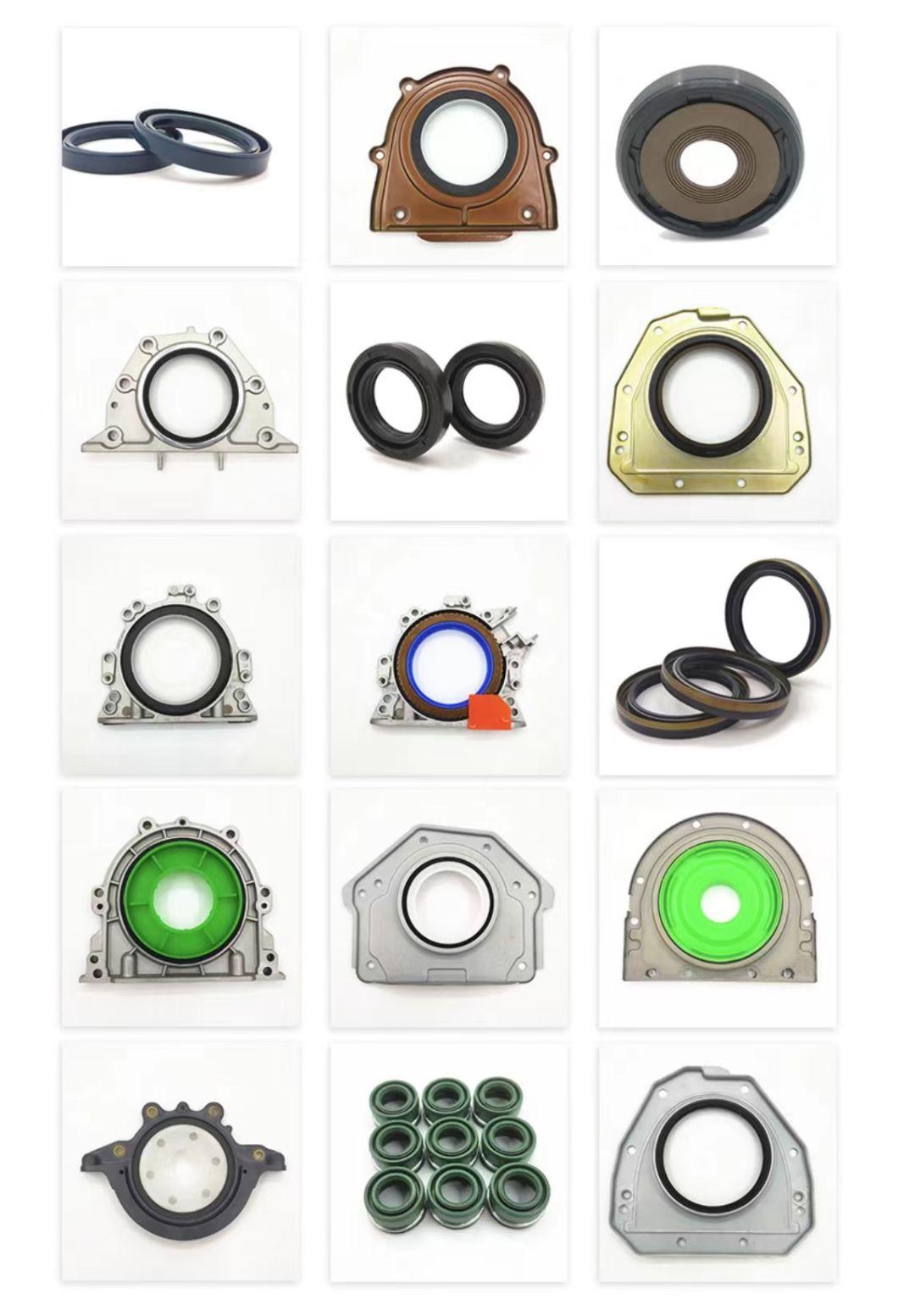

Oil seals are generally divided into single type and assembly type, assembly type is the skeleton and lip material can be freely combined, generally used for special oil seals.

From the sealing effect, characteristics, structure type, working state and sealing mechanism of oil seal can be divided into many forms and different names, but generally the rotary shaft lip seal ring is called oil seal, static seal and dynamic seal (general reciprocating motion) with seals called seals.

The representative form of oil seal is TC oil seal, which is a kind of rubber fully covered with self-tightening spring double lip oil seal, generally speaking, oil seal often refers to the TC skeleton oil seal.

Oil seal commonly used materials are: nitrile rubber, fluorine rubber, silicone rubber, acrylic rubber, polyurethane, ptfe and so on.

NBR nitrile rubber (NBR)

It has good heat resistance, wear resistance, resistance to all kinds of lubricating oil, grease, oil and gas mixture, suitable temperature of -30~120 degrees Celsius, but can not be phosphate ester hydraulic oil and containing extreme pressure additives in gear oil, in gasoline and low aniline point mineral oil stable performance.

Polyacrylate rubber (ACM)

Excellent oil resistance, heat resistance, wear resistance, ozone resistance, uv radiation resistance, especially resistance to extreme pressure liquid agent containing lubricating oil, gear oil, motor oil, oil, petroleum hydraulic oil, suitable for -30~150 degrees Celsius range of work.

Fluorine rubber

Aging resistance, heat resistance, oil resistance, almost suitable for all lubricating oil, fuel oil, gasoline, in the oil containing extreme pressure additives is not easy to harden, but cold resistance, high temperature wear resistance is poor, permanent compression deformation is large, suitable for temperature -20~250 degrees Celsius.

Silicone rubber

With outstanding high and low temperature resistance, can be used for a long time at 150 degrees Celsius without performance change; It can be used continuously for 10000h under 200, and can keep its unique advantages of flexibility and ozone resistance and weather resistance within the operating temperature range of -70~260.

Teflon

It has outstanding chemical stability, thermal stability, antifriction and self-lubrication, and its cracking temperature is above 400. Therefore, it can work in the temperature range of -200 to 300 degrees Celsius. In addition to free fluorine and alkali metals, it has excellent corrosion resistance to chemicals, solvents, hydroxyl compounds and acids.

Nitrile rubber compared with fluorine rubber material is to use a wide range of oil seal, the cost is low, but the heat resistance and sealing has improved significantly, but the cost is higher, and still have some adverse commonness of ordinary rubber materials, such as poor wear resistance and short service life, particularly sensitive response to the eccentric shaft, such as leakage phenomenon is relatively common. PTFE oil seal is a high technical content of products, is the future direction of oil seal development.

When selecting the material of oil seal, it is necessary to consider the compatibility of the material to the working medium, the adaptability to the working temperature range and the ability of the lip to follow the high-speed rotation of the rotating shaft. The temperature of the lip edge of the general oil seal is 20~50ºC higher than the temperature of the working medium, so attention should be paid to the selection of oil seal materials. The working range of oil seal is related to the material used for oil seal: the material for nitrile rubber (NBR) is -40~120ºC, Alec rubber (ACM) -30~180ºC, fluorine rubber (FPM) -25~300ºC.